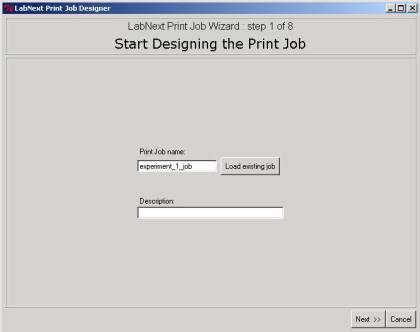

Job Wizard

Print Job Design and Execution.

The Job Wizard software allows

creating and editing the print jobs. Print jobs recorded to the database serve

as instructions for the spotter control software - Jobcontrol.

Start creating the print job with

a name that later will be used to start spotter to execute this job.

It is recommended to use

relatively short names for the print jobs, keeping in mind that it will be

necessary to input them form the keyboard in the Windows Command Prompt. The

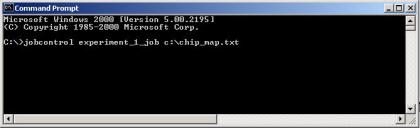

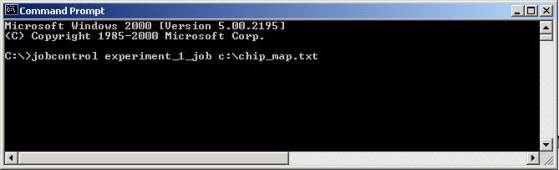

job with the name shown at the screen shot above can be launched for execution

with the following string in the Command Prompt:

The Job Wizard prompts to save the

new name in the database before moving to the next screen in the wizard. Later

this name can be used for searching and editing the print job. Once an existing

job is edited it can be saved under the current name or under a new name at the

last step of the Job Wizard.

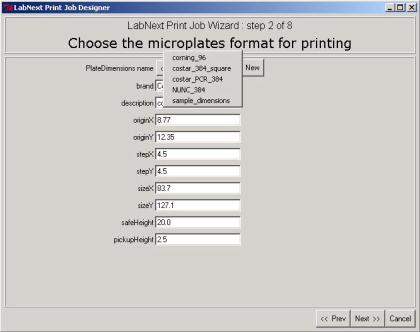

Step 2.

Microplate Specification

At the second step the Job Wizard

requires to specify parameters of the micro plate that will be used for

printing. Dimensions of micro plates of different vendors may vary

significantly. It is necessary to take measurements shown at the drawing below

or to find the dimensions using vendor's specifications.).

The measured parameters have to be

entered in the form at the step 2 of the Job Wizard and saved under a unique

name (COSTAR_384_PCR for example).

Once measured and registered the

micro plates can be used in the print jobs in the future by selecting the

relevant name. Their geometrical parameters will be automatically fetched from

the database.

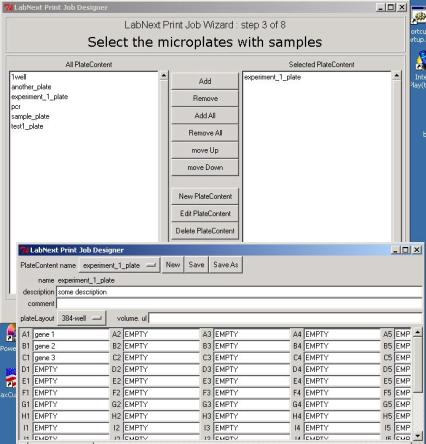

Step 3. Registering Plates Content. Selecting Source Plates for the Microarray.

At this step positions of the DNA

clones in the source plates are being registered. Open the plate image form by

pressing the <New Plate Content> button. Pressing the <New Plate

Layout> button initializes a 384-wells plate with all wells empty. An empty

well must be marked by the "EMPTY" string and will be ignored by the

spotter. Any other string, even the blank one will be considered as a clone

name by the software and the corresponding well as containing a clone.

When printing with more than one

needle the spotter may sink needles in empty wells. Sometimes if the microplate

have been filled with a multi-channel instrument, some wells may contain only

the printing buffer with no DNA in it. Needles will be leaving spots on the

substrate surface with close to background intensity. These spots will not be

annotated.

It is makes sense to annotate

filled wells with the name of the clone in them.

In order to select microplates

that will be used in this print job from the available microplates it is

necessary to mark them in the left panel "All Plate Content" and

pressing the <Add> button move them to the right panel "Selected

Plate Content". All DNA clones from the plates listed in the right panel

will be printed on the microarray. The <Remove> button excludes selected microplates

from the print job but not deletes them from the database. If there is more

than one microplate assigned for the print job the spotter will be stopping in

order to replace microplates that have printed with the new ones. The spotter

will print microplates in the same order they listed in the right panel

"Selected Plate Content". Pressing the <move Up>, <move

Down> buttons allows to change the order of microplates in the window and

therefore the printing sequence.

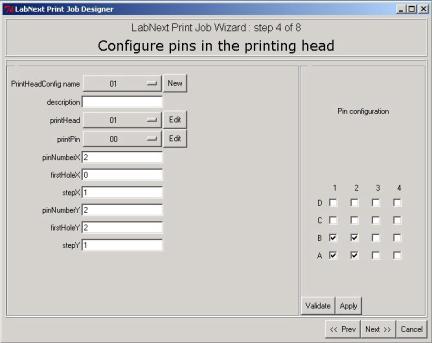

Step 4.

Printing Head Configuration.

The configuration deals with

specifying head type, printing needles type and their positions in the head.

Although it is possible to edit geometrical specifications of printing heads

and needles form this program it is not recommended. There is a special program

named "Configure System" designed specifically for registering all

tools and configuring the system before the operations.

Each printing head configuration

can be saved under a unique name by pressing the button next to the "PrintHeadConfig name" label.

Similar buttons next to the "printHead" and "printPin"

labels open lists of heads and needles that have been registered already in the

database.

The number of needles and their

positions in the head can be edited in the right part of the "Pin

Configuration" window. On the 4x4 head pattern it is necessary to mark the

check boxes that correspond to the positions of needles in the real head. The

<Validate> button initiates configuration validity check. A number of

asymmetrical configurations not allowed and the system will generate the error

message in case eon of them has selected.

The <Apply> button registers

selected head configuration in the database. The numeric fields in the left

part of the window change their values according to the logic of selected

configuration.

Step 5.

Design of Microarray Pattern.

It is recommended to pay extra

attention to this step because positioning of spots on the chip strongly

affects quality of the following hybridization and scanning. It is an expedient

approach using one and the same microarray pattern for a logically linked

series of experiments. This can significantly improve data consistency.

Chip patterns can be saved in the

database under unique names and reused later for another microarrays. In order

to select a pattern that's already saved in the database it is necessary to

click the button next to the <Pattern> label. Patterns do not depend on

the DNA clones suppose to be printed on the microarray it is just a template to

deposit them.

The program allows designing

microarray pattern in the semi-automatic and manual modes. The semi-automatic

mode is the default one. The

<Advanced> button starts the manual mode.

In order to specify microarray

pattern it is necessary to fill out the fields in the "Desired

Pattern" panel. Please refer to the Print Geometry section of this manual

for additional information.

Number of Samples - not editable.

Shows the total number of clones form all plates assigned for printing in this

job.

Spots per sample - number of

repetitions for each clone. Duplicates of spots can be used for controlling

data repeatability in the experiment.

Arrays (zones) per slide - number

of identical arrays on one substrate. Arrays will be placed along the vertical

(long) side of the substrate.

Spot distance mm - spacing between

spots measured in millimeters.

Extra cluster distance mm -

distance between clusters OVER the minimal distance that keeps clusters from

overlapping.

Extra quad distance - distance

between quads OVER the minimal distance (that is equal to distance between the

needles)

The last two parameters limit

maximum allowed spots in the pattern. It makes sense to set them more that 0

only in case of the risk of spots merging during the printing of microarrays.

Enter 0 value in these fields to

let the program design the optimal pattern automatically. The pattern will be

created based on the following principles:

- The work surface of the

substrate logically divided into identical rectangular areas equal in number to

the number of zones (arrays) suppose to be printed on the substrate. Each array

will be printed in geometrical center of the corresponding zone.

- Each cluster of spots will be printed in 1xN pattern (as a

horizontal line).

- Extra quad distance will be set to maximum value that allows to

accommodate all required spots on the array.

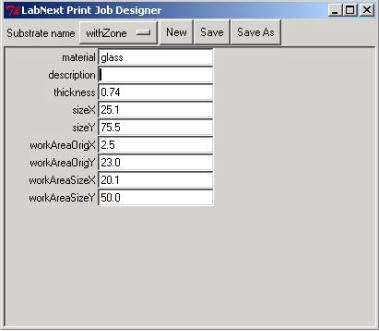

Registering and Editing Parameters

of Substrates.

Clicking on the <Edit>

button right form the "Substrate" label opens the substrate

parameters window.

Meanings of the fields are:

- material - material that the substrate made out. (glass,

nylon, etc.)

- description - free format description. Non-mandatory field.

- thickness -

substrate thickness

The rest of parameters explained at the picture below.

It is possible to save parameters of substrates in the database and use them just selecting an appropriate name without editing the parameters before each printing.

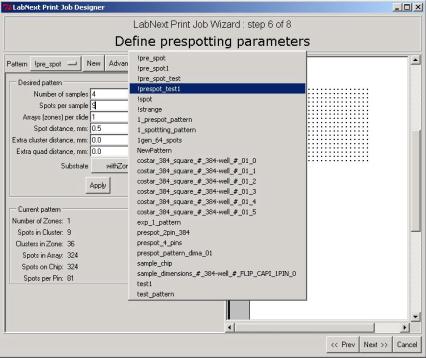

Step 6.

Design of Prespotting Pattern.

Prespotting is the deposition of a

number of spots on a separately assigned substrate (prespotting substrate) in

order to remove excessive liquid from tips of the needles right after samples

pick-up. Number of prespotting spots depends on the type of needles, material

of the substrate, viscosity of printing buffer and environmental conditions -

temperature and humidity. For the LabNEXT composite capillary needles this

number ranges from 1 to 6. In case of using a new printing buffer, other than

the LabNEXT printing buffer it is recommended to make a few test printing runs

in order to determine the number of prespotting spots require. Editing of

prespotting patterns is totally identical to editing the microarrays patterns.

Main criteria for designing of

prespotting patterns though differ form ones used for microarrays patterns. It

is recommended to by guided by the following principles:

- Use minimal possible number of

prespotting spots in order to save space on the prespotting substrates.

- It is possible to reduce the

distance between spots in comparison to the distance between sports in

microarrays and allow spots merging WITHIN ONE CLUSTER. A cluster consists of

spots with one and the same clone therefore there will not be risk of

contamination with adjacent clones.

- Clusters must not merge. To

prevent them from merging set the Extra Clusters Distance to a >0 value.

- Try to use fully the surface of

prespotting substrates.

- One and the same prespotting

layout can be used in many print jobs.

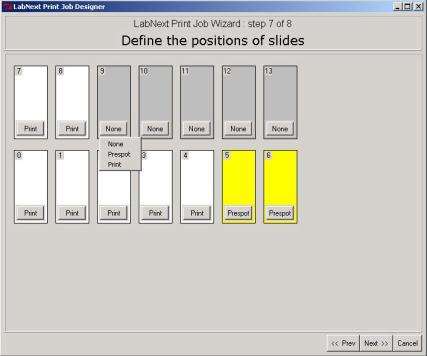

Step 7.

Placing Substrates on the Work Board of the Spotter.

Substrates can be placed in any

slide nests in any order. Press the button in the lover part of the image of a

slide nest to register positions of the glasses on the board. Register all

substrates in the way they are placed on the work board. The spotter prints

starting form the right lower substrate clockwise. It is better to put

prespotting substrates in the first positions on the printing path. Empty

positions will be ignored. If there are not enough prespotting substrates to

accommodate all prespotting spots the print run will be suspended and the

spotter control software will generate the message prompting to replace

prespotting spots.

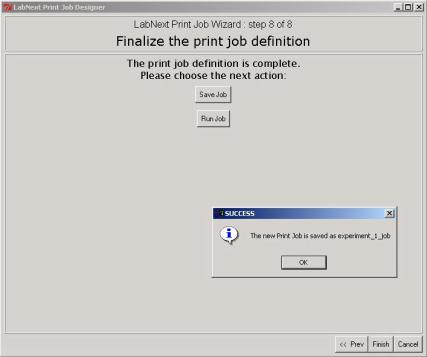

Clicking the <Save Job>

button can save print job. If there are unsaved changes the program will prompt

to save the job before finalizing the Job Wizard.

A print job launches from the

Windows Command Prompt that ca be found at StartàProgramsàAccessories.

Type in the Command Prompt window

the following string:

Jobcontrol [job name] [annotation

file path and name]

[job name] - name of a print job

you want to execute

[annotation file path and name] -

name of the file generated by the spotter that will be used by other

application for annotation of clones on the microarray images. There are no

limitations on the naming this file.